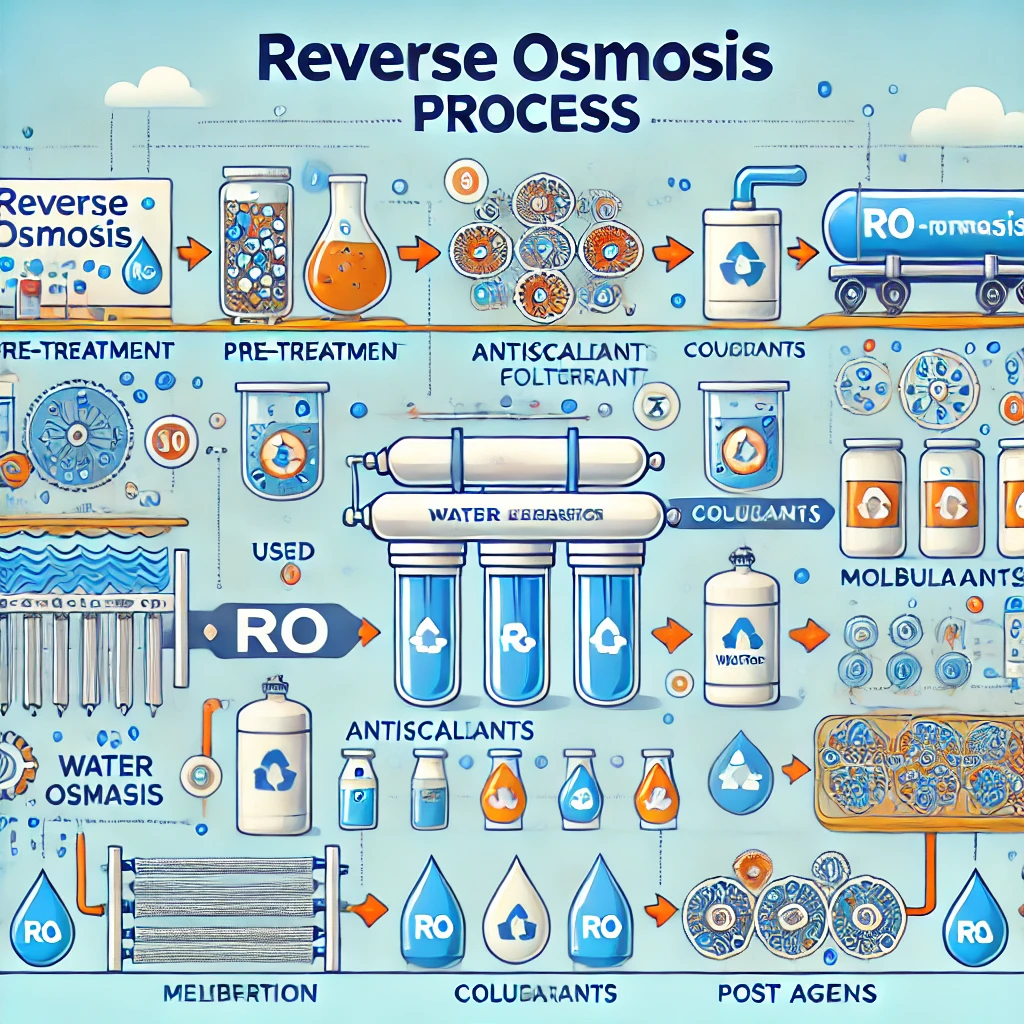

Essential Solutions for Reverse Osmosis Systems

Reverse Osmosis (RO) systems are widely recognized as one of the most effective methods for purifying water, providing clean, safe drinking water for both domestic and industrial applications. However, to maximize the efficiency and lifespan of RO plants, the use of specialized chemicals is essential. These chemicals play a critical role in pre-treatment, membrane cleaning, and maintenance, ensuring that the RO system operates at peak performance.

1. Types of RO Plant Chemicals:

Key categories of chemicals used in RO plants for optimizing water purification processes include:

- Antiscalants: These chemicals prevent the formation of scale on RO membranes by inhibiting the precipitation of minerals such as calcium carbonate, sulfate, and silica. By maintaining membrane cleanliness, antiscalants enhance the efficiency and longevity of the RO system, reducing downtime and maintenance costs.

- Coagulants and Flocculants: Used in the pre-treatment phase, these chemicals help in aggregating suspended solids, organic matter, and other contaminants present in the feed water. Coagulants, such as polyaluminum chloride (PAC), neutralize the charges of suspended particles, while flocculants promote the formation of larger flocs for easier removal during filtration processes.

- pH Adjusters: Maintaining the appropriate pH level in the feed water is crucial for optimal RO operation. pH adjusters, such as sodium hydroxide or sulfuric acid, are used to either raise or lower the pH to prevent membrane damage and improve the efficiency of coagulants and flocculants.

- Biocides: These chemicals are essential for controlling microbial growth in RO systems. Biocides, like chlorine or non-chlorine based alternatives, help prevent biofouling, which can clog membranes and reduce system performance. Regular application of biocides is critical, especially in systems treating surface water or water with high organic content.

- Cleaning Chemicals: Over time, RO membranes can accumulate fouling from organic materials, minerals, and other contaminants, necessitating periodic cleaning. Cleaning chemicals such as citric acid, sodium hydroxide, and hydrogen peroxide are formulated specifically to restore membrane performance by removing deposits and organic buildup without damaging the membrane structure.

2. Importance of Using RO Plant Chemicals:

The proper use of RO plant chemicals is vital for several reasons:

- Improved Water Quality: By effectively removing contaminants and preventing scale buildup, RO plant chemicals ensure that the purified water meets health and safety standards, making it suitable for drinking and industrial applications.

- Enhanced System Performance: Regular application of the right chemicals helps maintain the efficiency of the RO system, resulting in higher permeate flow rates and lower operational costs.

- Prolonged Membrane Life: Membranes are one of the most significant investments in an RO system. By preventing fouling and scaling, the appropriate chemicals can extend the lifespan of the membranes, leading to substantial savings in replacement costs.

- Reduced Downtime: Efficient pre-treatment and maintenance minimize system downtime, allowing for uninterrupted operations in both residential and industrial settings.

3. Best Practices for Chemical Management:

To maximize the benefits of RO plant chemicals, consider the following best practices:

- Regular Monitoring: Conduct regular water quality tests to determine the appropriate types and doses of chemicals required for effective treatment.

- Professional Training: Ensure that operators and maintenance personnel are well-trained in the proper handling and application of chemicals to avoid mishandling and ensure safety.

- Supplier Collaboration: Work with reputable chemical suppliers who can provide guidance on the best products for your specific RO system and water quality challenges.

- Environmental Considerations: Choose eco-friendly chemical options whenever possible to minimize environmental impact and promote sustainable water management practices.

Conclusion:

In summary, RO plant chemicals are essential components of an efficient and effective reverse osmosis water treatment system. By selecting the right chemicals and following best practices for their application and management, users can achieve optimal water quality, prolong the lifespan of RO membranes, and enhance the overall performance of their water treatment systems. At Spa Plus International, we are committed to providing high-quality RO plant chemicals tailored to meet your specific needs, ensuring that your water purification processes are both effective and sustainable.